The hot open-cast process provices a long slow cure and post-cure that enhances the cross-linking of the polyurethane molecules. Although open-cast thermoset polyurethane components are more labor-intensive to manufature, the result is a greater range of advanced physical properties which results in better wear and overall life performance as well as a significant cost savings.

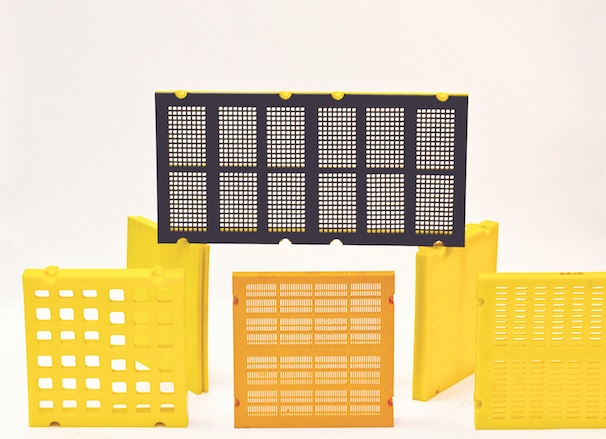

WS 85 Modular Screen™

WS 85 screen panels are made with the highest quality, mine duty, open cast urethane available anywhere in the world! They are manufactured and supplied in a range of durometers and custom structural designs to meet any and every screening application. From fine wet and dry screening to primary scalping and every other screening application in between – TEMA ISENMANN WS 85 screen panels are plant proven to be the best.

- The standard for 1' x 4' and 1' x 2' modular panel systems

- Exclusive staggered pattern for increased efficiency

- Openings from 0.2mm to 8"

- 30 to 100mm thick panels; can include dams and diverters

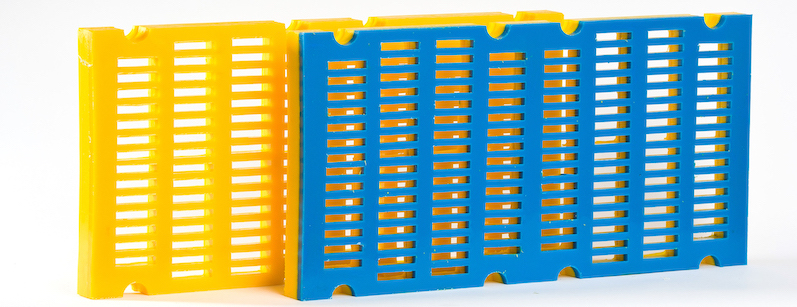

Flex-A-Thon™

- #1 screen media for tight separations when fine screening up to 6% damp material

- Guaranteed non-blinding and long wear life

- Prevents blinding while allowing the use of square openings in fine dry screening

- Preferred screening media for wet dust suppression

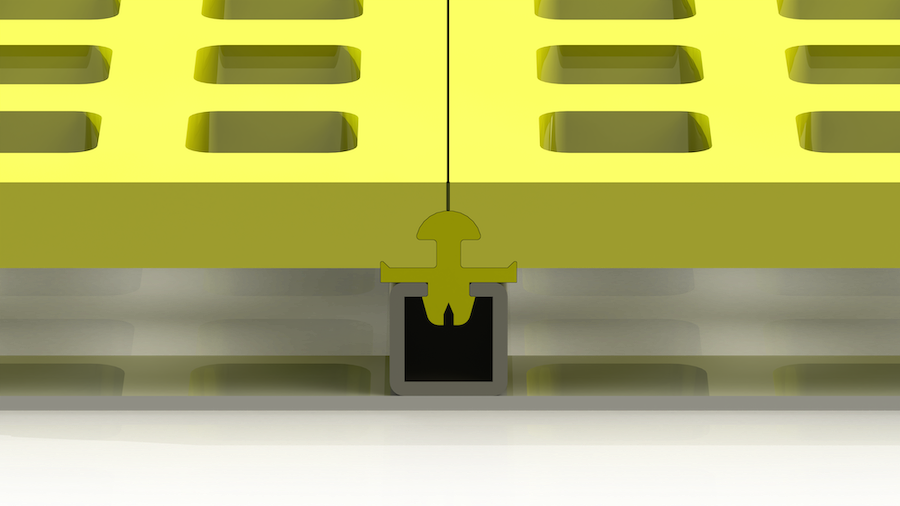

Polyurethane Pin & Leg Systems

Modular open-cast Polyurethane Pin & Leg Panels are compatible with all 1' x 1' and 1' x 2' systems.

- Proprietary TDS aperture design creates flexible non-blinding panels

- Hi-flow system offers reduced margins for increased open area

- Solid pin design for quick, easy installation & removal

Boltdown & Tension Systems

- Boltdown panels are designed and manufactured to suit the application

- Steel-backed reinforcement for high impact resistance

- Materials are available to optimize wear life

- Options range from soft urethane with excellent impact resistance to higher durometer suited for fine, wet applications

Tension screens are cable-reinforced and custom-made to fit any crown deck

Direct replacement for single and double crown side tension configurations

End tension designs are also available

Let Us Help

Are you looking for products to save time and reduce costs? Contact us. Even if you don’t see what you’re looking for on our site – we custom build solutions to customer problems. Think Yellow!