Our EXCLUSIVE, PATENTED WS 2.10 is a high-quality polyurethane that can be applied to any steel surface. WS 2.10 systems deliver custom solutions for all your wear and screening needs with amazing quick-install, no-bolt, no-glue, no-weld systems.

WS 2.10 Magnetic Wear Liners

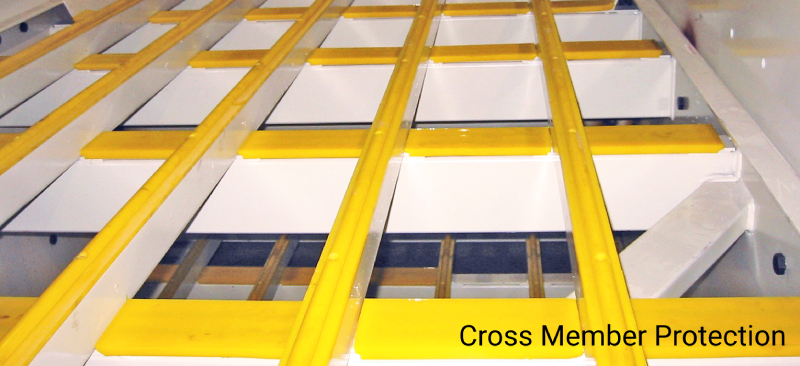

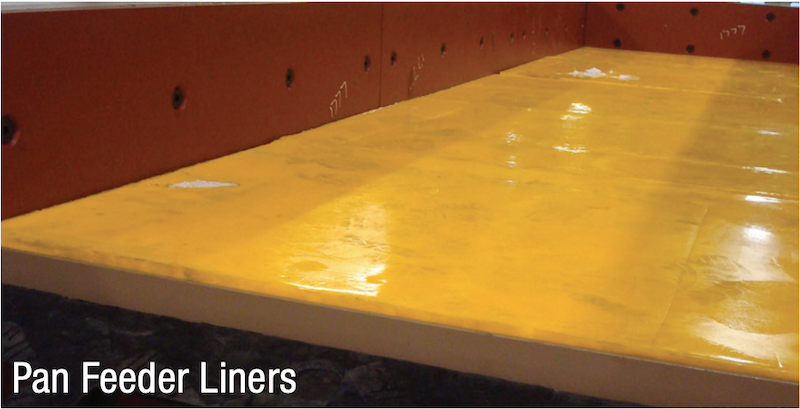

WS 2.10 Magnetic Wear Liners can be applied to any steel surface that sustains wear. Premature wear is successfully conquered in static or vibratory applications — no problem! For use as: Frame Protectors, Tube Covers, Discharge and Feed Lips, Chute and Pan Liners. WS 2.10 Wear Liners protect your investment!

- No welding or cutting

- Easy wear rotation

- Quick installation and removal

- Stays securely in place

US Patent No. 8,287,791

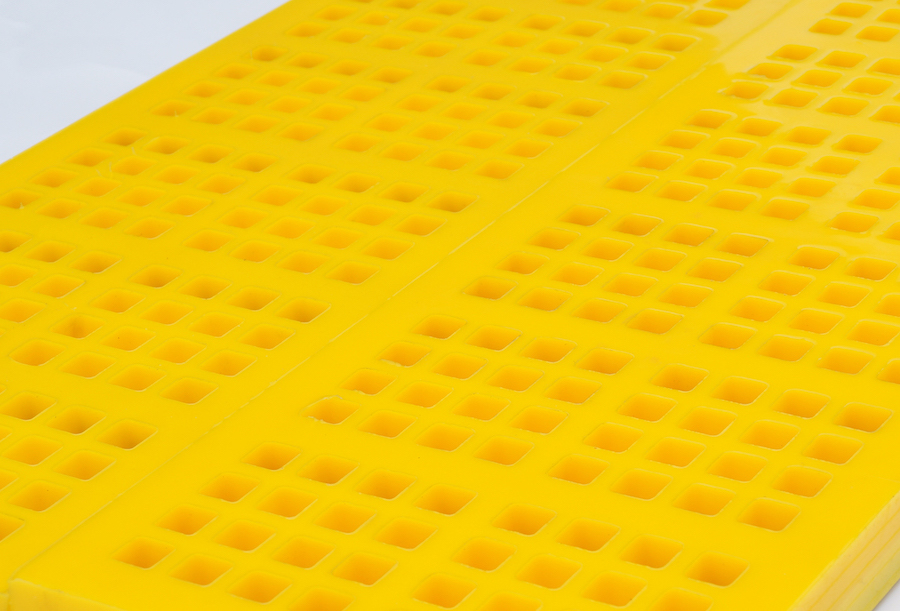

WS 2.10 Screening Media

WS 2.10 Screening Media, our revolutionary screening solution, can be applied to any steel surface designed for a screen. Quick install and superior screening solutions are available in 30, 40, and 50mm panel thickness and easily installed on WS 85 girders, Kombi Rails, etc. WS 2.10 Screening Media takes screening to the next level! US Patent No. 9,283,700

Easy Install

Snaps in Place

No Tools Required

Let Us Help

Are you looking for products to save time and reduce costs? Contact us. Even if you don’t see what you’re looking for on our site – we custom build solutions to customer problems. Think Yellow!