TEMA ISENMANN supplies the full range of Multotec Optima Wedgewire products and a full range of profiles available in 430, 304 and 316SS, including:

Seamless Wedgewire Cylinders for CIP / CIL Interstage Screens

Kambalda Screens

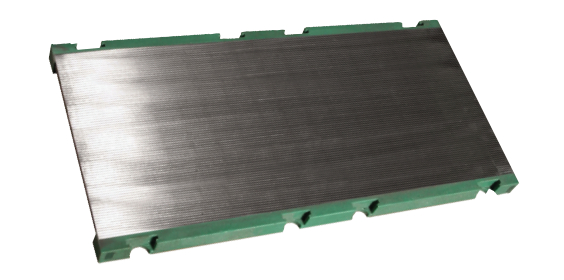

Wedgewire Panels

Panel sizes to suit screen deck.

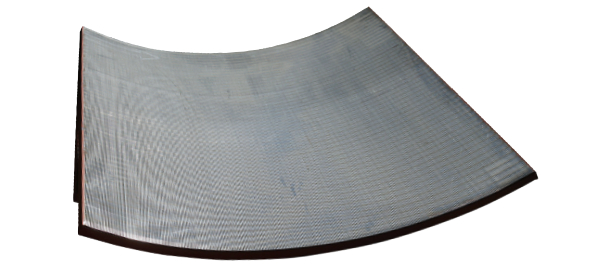

Wedgewire Sieve Bends

Available in different wedge wire profiles and aperture sizes.

WS 85 Wedgewire Panels

Available in 1'x2' and 1'x4' with different apertures and wedge wire profiles to suit the application.

Hybrid Poly-Wedge Panels

Modular 305x305x30mm with different wedge wire profiles and apertures to suit the application.

Let Us Help

Are you looking for products to save time and reduce costs? Contact us. Even if you don’t see what you’re looking for on our site – we custom build solutions to customer problems. Think Yellow!