Screens Offer New Era in Process Efficiency

E&MJ presents the latest developments in vibratory screening technology from eight leading vendors

By Carly Leonida, European Editor, Full Article Here

TEMA ISENMANN manufactures a range of open-cast and injection molded polyurethane screen panels, as well as patented magnetic liners and panels at its base in Lexington, Kentucky. It primarily supplies the North American mining and aggregate markets including the USA, Canada and Mexico using direct sales personnel and a network of dealers.

“We have recently installed a ve-axis CNC milling machine to increase the capacity for manufacturing our own tooling in house, and we have also increased our manufacturing capability substantially by automating parts of the plant,” explained Anthony Yell, manager of TEMA ISEN-MANN’s Mining Division.

“Our open-cast polyurethane prod-ucts have extremely good abrasion and impact-resistant properties, so for ag-gressive applications we tend to use open-cast polyurethane that will generally improve life by at least twice that of injec-tion-molded panels.

“There are lots of options available in different durometers from 60 to 90 shore A. In addition, we manufacture a range of dual durometer panels where we combine a soft 60 shore polyurethane top layer with a harder base in different colors. This not only improves certain screening appli-cations, but the different colors work as a wear indicator — when you wear through the top blue layer and expose the bottom yellow layer, it’s time to replace the pan-els. This versatile range of materials and panel sizes allows us to manufacture pan-els to suit most applications.”

TEMA ISENMANN’s range of injection molded modular panels are avail-able in 1- x 1-ft sizes and are generally used for ne screening applications down to 300 microns.

“Since we are part of an international group of companies involved in the mining industry [that includes Steinhaus GmbH; Isenmann Siebe GmbH; Tema Group and Multotec Group], we also have access to numerous other screen media and mate-rials,” added Yell. “These include compression molded and injection molded rubber panels, and hybrid Poly-Wedge panels that have a combination of stainless-steel wedge wire mats fastened to a polyurethane frame. This means they are consistent with the modular concept of 1- x 1-ft, 1- x 2-ft and 2- x 2-ft panel sizes.”

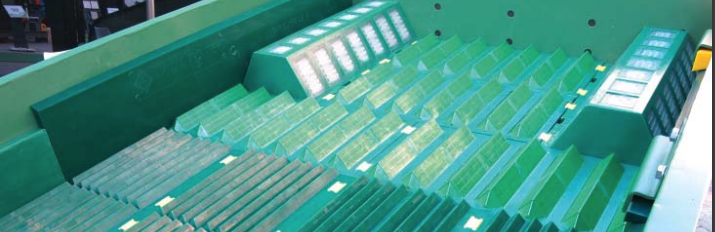

TEMA ISENMANN also offers a range of TeePee high open-area, 3D panels that typically have double the open area of conventional at panels, which results in double the drain rates. These can be used to increase the dewatering capacity of ex-isting dewatering screens or allow the cli-ent to install smaller dewatering screens.

“We regularly assist in checking screening sizing too, especially when clients want to convert from say woven wire to polyure-thane to ensure they still have suf cient screening capacity available,” added Yell. “We make use of programs such as Agg-Flow to check mass balances, screening area and screening ef ciencies.” The company recently converted a number of mill discharge screens from conventional injection molded panels to open-cast polyurethane, and has more than doubled the life in many of these applications.

Yell explained: “With regard to new products, we are continuously growing and improving our range of apertures in both open-cast and injection molded panels. Our range of WS2.10 patented magnetic panels assist clients with reduced maintenance down time, especially on second and third decks where panels are noto-riously dif cult to replace due to space constraints. They are quick to remove and replace safely with minimal tooling.”

Yell said the WS2.10 magnetic lin-ers are proving exceptional in reducing downtime and, as there is no bolting required, there is no need for cutting and grinding equipment, which improves the safety of installation and removal. Another bene t is that plants can now standardize liners as they no longer need to keep left and right-hand versions, re-ducing inventory and costs. The Saddle Top Rail System that has proven itself over the last 15 years in Africa and Australia, will be launched at MINExpo for the North American market and is fully compatible with existing runner systems.

“It has proven to be far superior to most runner systems in the market not only because it extends runner life and is quick and easy to replace, but it sup-ports the internal frame of the screen panels properly,” said Yell. “The polyure-thane-polyurethane interface extends the panel life as well.”

TEMA ISENMANN’s WS85 panels, rub-ber screen panels, Poly-Wedge screen pan-els and WS2.10 magnetic liners and screen panels will also be on show at MINExpo.

“Our new magnetic-backed stroke gaug-es will be available free of charge to dele-gates,” added Yell. “These are really useful devices for checking whether a vibrating screen is operating to manufacturer specications. There are a couple of other things we have up our sleeve too, but we don’t want to give the game away at this time.”

Let Us Help

Are you looking for products to save time and reduce costs? Contact us. Even if you don’t see what you’re looking for on our site – we custom build solutions to customer problems. Think Yellow!